The Remedy Lies In Empathy!

Do you ever use your 2-in-1 weeder hoe and think, 'golly this could be improved so much!'? Well, I did too! I often would use my own 2-in-1 weeder hoe and have a strain on my arm and back muscles. When talking to older gardeners I found that a lot of tools, besides sometimes just being inconvenient for some, are not catered at all for older folks. Luckily I was taking a class called Design & Engineering at the time I found out this information. In this class, I have been learning about volume, surface area, and vectors, the design process and how empathy plays a huge role in it.

Empathy, in my opinion, means being able to recognize, be aware, and be influenced by someone's feelings. Empathy played a huge role in my redesigning of a 2-in-1 weeder hoe since we also studied how difficult everyday tasks can be for older folks. My new and improved Wheeler Weeder Hoe, made with the help from my partner MT, is lightweight, easy to use, and efficient!

What one must always do first when designing is research, research, research! As such, our class conducted some hands-on research by actually working in a garden, first with just our hands and then with actual tools. This was to get a feel for the equipment, how they helped, and maybe how they didn't work. After this, we went on an FE (Field Experience) to our local Home Depot to talk to one of the tool experts.

One quote I took away from this interview was "Basically the easier it is the more people will use the tool..." Our tool master also explained that usually, you need to make at least 3 different versions of the same tool. He gave us the example of a tool that is single-use, every once in awhile use, and heavy-duty use. He also told us a very well known fact from the design process, you must listen to the people using the tools if you want to improve them and sell them.

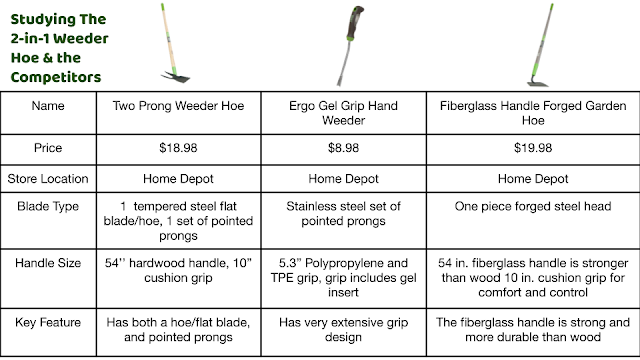

Now besides talking to someone who sells tools and interacts with customers, I also talked to a customer who uses said tools. If you want to see that small project check it out here! Doing all of this research should be enough to start designing right? GUESS AGAIN! After looking at things from a broad and general point of view we have to get into the nitty-gritty, comparing our original tool to competitor tools!

As you can see, just between our original tool and its competitors there are a lot of differences-in weight, material, length, and cost. Plus none of these tools seem to be accessible to older people who might have arthritis, bad knees, or general body disabilities. We can go more in-depth about all of this later.

Here it is, the Wheeler Weeder Hoe (WWH) in all its glory. With its thermoplastic gel grips for amazing grip even for the loosest and weakest of hands. Stylish, light and sustainable recycled plastic body make for an eyecatching tool. The ethylene-propylene rubber wheels are lightweight but durable, ready for any terrain. The adjustable height caters to people of all sizes, and the back balance wheel allows you to lean a bit on your WWH when you're feeling a bit weak in the knees. And, of course, the sharp yet portable iron hoe and weeder wheel are the best for getting all those pesky weeds and softening your terrains soil!

Here is a short storyboard on how to clean, use, and store your WWH.

Now, how exactly does the tool work? Using some simple vectors you can see that the forces you place on the handles travels down to the large weeder wheel. From there the wheel turns, transferring the force from before onto the conveyor belt which moves a small gear that makes the hoe go up and down without any extra force being exerted from the user!

The WWH is more efficient because it uses a few simple machines, for example, the pulley and the wheel, but it also uses a wedge. The hoe is a perfect example of a wedge having one end be sharper to be able to slice into the tough soil and create a soft bed for your seeds. The hoe also moves without extra force making it much more efficient. Talking about efficiency, we can now call back to the original tool we looked at and the competitors. As you can see the WWH is a lot different from all of the other tools. For one all of the other tools require a lot more force coming from the user, for example, the hand weeder would need the user to bend down and use a lot of force to pull out a weed themselves. Another thing is that the 2 prong weeder hoe and the garden hoe are very long and heavy, they also require some sort of swinging, something many old people wouldn't be able to do. With the WWH, the user is not required to do any other thing besides pushing the tool, no inefficient swinging, bending, or unnecessary exertion of force. The WWH is also the only tool that is truly 2-in-1 since the user doesn't have to exert two actions to complete two tasks, the pushing moves both the weeder wheel and the hoe, unless the user wishes to remove the hoe.

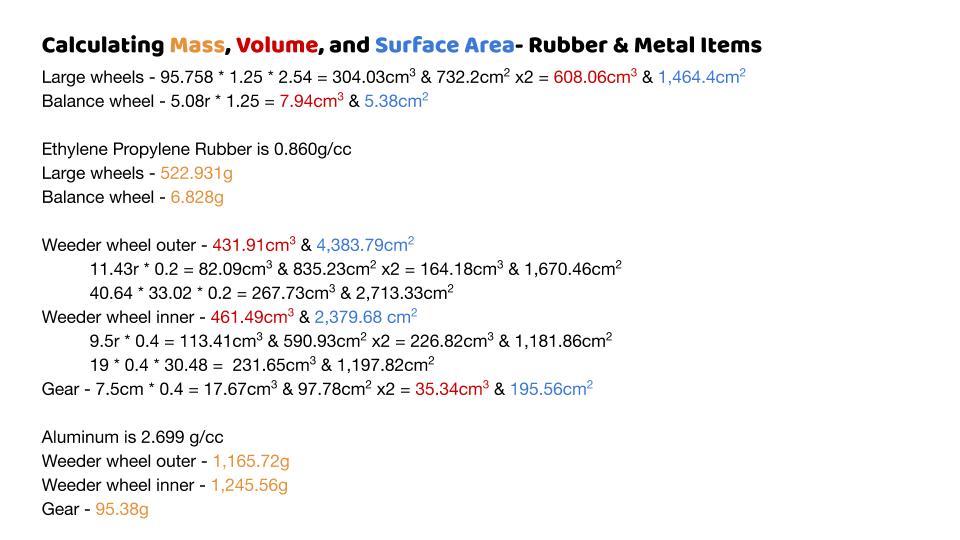

Now for exact certainty, I decided to separately calculate the approximate mass, volume, surface area, and cost of the whole machine. I chose certain materials to have an exact weight and cost reference. Now the estimate you see here is probably a bit off since I calculated simply for raw materials in terms of price. Most likely if I were to make this a real tool I would need to purchase molds for the tool, the materials, pay people to work the machinery to create the tool, pay for the electricity that goes into working the machines, advertisement, etc. But for simply the raw materials needed to make this I estimate around 6 dollars (excluding taxes and shipping) and the weight will be around 17 pounds!

Overall I learned a lot about why empathy is important in tool design and engineering. I took a course over the summer about graphic design, so this class felt like an extension of that course. Of course, tool design and graphic design are fairly different, but I think a few things overlapped and improved how I made my tool. The making of the tool and designing something new was fairly easy and fun for me, but since this was a partner project I felt like I was lacking in that department. I feel like I didn't communicate enough with my partner and that we almost made different projects, but this is a learning experience. Next time I will try to communicate with them more and take their input every step of the way.

Citations.

A&C Plastics Inc. Guide to Plastic Weight. www.acplasticsinc.com. N/A. Accessed Oct. 1, 2019.

RecyclingMarkets.net Staff. The latest on recovered plastics pricing. resource-recycling.com. Dec. 13, 2017. Accessed Sept. 30, 2019.

Empathy, in my opinion, means being able to recognize, be aware, and be influenced by someone's feelings. Empathy played a huge role in my redesigning of a 2-in-1 weeder hoe since we also studied how difficult everyday tasks can be for older folks. My new and improved Wheeler Weeder Hoe, made with the help from my partner MT, is lightweight, easy to use, and efficient!

What one must always do first when designing is research, research, research! As such, our class conducted some hands-on research by actually working in a garden, first with just our hands and then with actual tools. This was to get a feel for the equipment, how they helped, and maybe how they didn't work. After this, we went on an FE (Field Experience) to our local Home Depot to talk to one of the tool experts.

One quote I took away from this interview was "Basically the easier it is the more people will use the tool..." Our tool master also explained that usually, you need to make at least 3 different versions of the same tool. He gave us the example of a tool that is single-use, every once in awhile use, and heavy-duty use. He also told us a very well known fact from the design process, you must listen to the people using the tools if you want to improve them and sell them.

Now besides talking to someone who sells tools and interacts with customers, I also talked to a customer who uses said tools. If you want to see that small project check it out here! Doing all of this research should be enough to start designing right? GUESS AGAIN! After looking at things from a broad and general point of view we have to get into the nitty-gritty, comparing our original tool to competitor tools!

|

| All tool images belong to HOME DEPOT |

As you can see, just between our original tool and its competitors there are a lot of differences-in weight, material, length, and cost. Plus none of these tools seem to be accessible to older people who might have arthritis, bad knees, or general body disabilities. We can go more in-depth about all of this later.

|

| GGS. Wheeler Weeder Hoe. 2019. |

Here it is, the Wheeler Weeder Hoe (WWH) in all its glory. With its thermoplastic gel grips for amazing grip even for the loosest and weakest of hands. Stylish, light and sustainable recycled plastic body make for an eyecatching tool. The ethylene-propylene rubber wheels are lightweight but durable, ready for any terrain. The adjustable height caters to people of all sizes, and the back balance wheel allows you to lean a bit on your WWH when you're feeling a bit weak in the knees. And, of course, the sharp yet portable iron hoe and weeder wheel are the best for getting all those pesky weeds and softening your terrains soil!

Here is a short storyboard on how to clean, use, and store your WWH.

|

| GGS. WWH Storyboard. 2019, |

Now, how exactly does the tool work? Using some simple vectors you can see that the forces you place on the handles travels down to the large weeder wheel. From there the wheel turns, transferring the force from before onto the conveyor belt which moves a small gear that makes the hoe go up and down without any extra force being exerted from the user!

|

| GGS. WWH Vectors. 2019 |

The WWH is more efficient because it uses a few simple machines, for example, the pulley and the wheel, but it also uses a wedge. The hoe is a perfect example of a wedge having one end be sharper to be able to slice into the tough soil and create a soft bed for your seeds. The hoe also moves without extra force making it much more efficient. Talking about efficiency, we can now call back to the original tool we looked at and the competitors. As you can see the WWH is a lot different from all of the other tools. For one all of the other tools require a lot more force coming from the user, for example, the hand weeder would need the user to bend down and use a lot of force to pull out a weed themselves. Another thing is that the 2 prong weeder hoe and the garden hoe are very long and heavy, they also require some sort of swinging, something many old people wouldn't be able to do. With the WWH, the user is not required to do any other thing besides pushing the tool, no inefficient swinging, bending, or unnecessary exertion of force. The WWH is also the only tool that is truly 2-in-1 since the user doesn't have to exert two actions to complete two tasks, the pushing moves both the weeder wheel and the hoe, unless the user wishes to remove the hoe.

Now for exact certainty, I decided to separately calculate the approximate mass, volume, surface area, and cost of the whole machine. I chose certain materials to have an exact weight and cost reference. Now the estimate you see here is probably a bit off since I calculated simply for raw materials in terms of price. Most likely if I were to make this a real tool I would need to purchase molds for the tool, the materials, pay people to work the machinery to create the tool, pay for the electricity that goes into working the machines, advertisement, etc. But for simply the raw materials needed to make this I estimate around 6 dollars (excluding taxes and shipping) and the weight will be around 17 pounds!

|

| GGS. So Many Numbers. 2019 |

Citations.

A&C Plastics Inc. Guide to Plastic Weight. www.acplasticsinc.com. N/A. Accessed Oct. 1, 2019.

RecyclingMarkets.net Staff. The latest on recovered plastics pricing. resource-recycling.com. Dec. 13, 2017. Accessed Sept. 30, 2019.

Comments

Post a Comment